Malt intended for use in beer brewing or elsewhere in the food industry

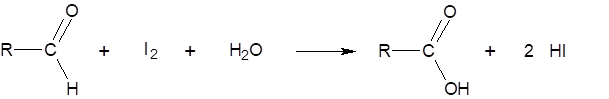

The aliquot of an extract of malt is added to a buffered starch solution and allowed to stand for exactly 30 min at 20 °C. Then, the maltose – formed primarily from the starch through the action of the β-amylase – is measured using iodine and is determined according to the following chemical reaction:

This method describes how to mill grain or malt to produce fine or coarse grist.

Malt intended for use in beer brewing or elsewhere in the food industry

Malt is ground between two horizontally positioned, grooved discs. The lower disc is driven by an electric motor and rotates at approx. 1500 rpm; the upper disc is fixed and therefore does not move. During the milling process, the malt migrates from the center of the discs to the outer edge, where the grist falls through an outlet spout into a grist beaker.

The gap between the discs can be adjusted by turning a socket head screw on a calibrated ring bearing scale markings. The scale on the calibrated ring ranges from 0 to 20, with each scale division corresponding to a gap between the discs of 0.10 mm. Each scale division is subdivided into five smaller divisions; each of the smaller marks is equivalent to 0.02 mm. Two gap adjusting rings ensure reproducible mill settings.

This method describes the fluorimetric determination of high-molecular weight β-glucans in laboratory worts.

Suitable for all types of (laboratory) worts

The fluorochrome Calcofluor forms a complex with high molecular weight β-glucans (molecular weight greater than 5 kDa). Complex formation results in an increase in fluorescence; however, this fluorescence is extremely unstable due to photochemical degradation.

Reproducible measurements for fluorescence and determination of β-glucan are possible through measurement in an automatic analysis system based on flow injection (flow-injection analysis). The apparatus is calibrated using purified barley β-glucan standard solutions.

The compounds in the malt dissolved in the mash liquor during a standardized mashing process using finely ground malt (fine grist) are determined in this analysis.

Malt intended for use in beer brewing or elsewhere in the food industry

The Congress mash method primarily serves to determine the extract content of malt.

The extract content is determined by the weight ratio sL 20/20 of the wort on the basis of the official sugar tables (Plato tables) at 20 °C. sL 20/20 stands for the weight ratio of a volume of wort at 20 °C to the same volume of water at the same temperature.

Furthermore, the following is tested over the course of this analysis: Iodine test (saccharification time), odor of the mash, wort run-off, clarity of the filtered wort; the Congress wort is also used as a basis for a wide variety of further analyses.

The method describes the conditions under which sensory analysis is to be conducted.

beer, beer-based beverages, non-alcoholic beverages, mineral water

One of the basic prerequisites for properly conducting sensory analysis is training the members of the tasting panel.

This method describes how to evaluate hoses, particularly beer hoses.

Hoses which are used in the brewing and food production industries

New hoses and/or those manufactured using unsuitable materials can bring about a change in the aroma or the flavor of the liquid passing through them. Pieces of hose are placed in a test medium of either beer or 96 % alcohol. After a defined period of time, the test samples are tasted and compared to control samples.